Ⅰ.The principle of measuring Coriolis force is advanced

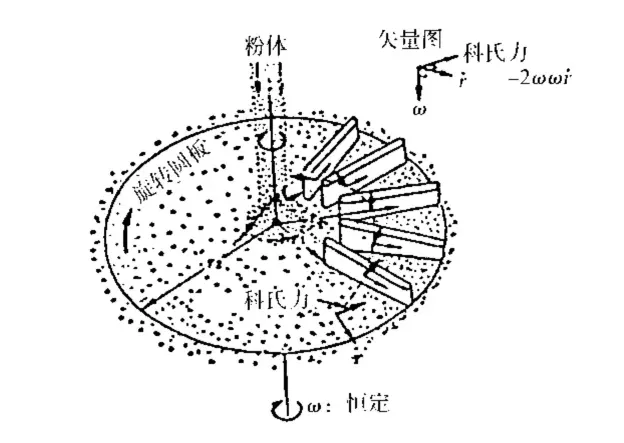

The core of Coriolis pulverized coal feeder is a measuring wheel driven by the main shaft. The measured material enters from the center of the measuring wheel and is thrown out from the rotating measuring wheel. The material will produce a force on the blade of the measuring wheel, which is the Coriolis force. The force is directly ratio to the mass of the material. The flow of the material can be obtained by measuring the force. In the Coriolis powder mass flowmeter, the torque of the drive shaft of the measuring wheel is measured. Because the radius of the measuring wheel is fixed, the measured torque obtains the Coriolis force, and indirectly obtains the instantaneous flow of the material. The friction between the material particles and themeasuring disk and the friction between the material layers with different speeds have no effect on the measurement results, which ensures the accuracy of the system.

Moment calculation formula:M = m·ω·R² 。

Where: M is the moment, ω Is the angular velocity of the measuring disk, and R is the radius of the measuring disk.

The calculation formula of Coriolis force is:Fd = 2·m·(V x ω)

Where: FD is Coriolis force, ω Is the angular velocity of the measuring disc, and V is the velocity when the material is thrown out of the measuring disc. Real time flow I:I = m x V

The integration of flow time is the amount of material Z:Z = I x t

Where: Z is the cumulative value; T is the integration time.

The “Coriolis” force is used to measure the flow, which measures the torque of the instantaneous material quantity, so as to measure the actual instantaneous flow.

Ⅱ. Structure and function

Coriolis pulverized coal feeder not only realizes high-precision continuous measurement of powder materials, but also has the characteristics of no dust pollution, simple structure, small volume, stability and reliability. Since there are no components outside the casing, it is not affected by wind, vibration or any other interference forces. It has the following characteristics:

◆Measuring accuracy of Coriolis pulverized coal feeder≤±0.5%

◆Coriolis pulverized coal feeder adopts Coriolis force principle to obtain the instantaneous mass flow of materials. Since the Coriolis force is only related to the size of the measuring wheel, external adverse factors (wind pressure, blanking, vibration, etc.) will not affect the measurement of Coriolis powder mass flowmeter, which effectively ensures the accuracy of measurement accuracy.

◆Coriolis pulverized coal feeder adopts gear force transmission mechanism and gas seal inside to ensure the stability of zero point and minimize the influence of zero point on metering.

◆Coriolis pulverized coal feeder adopts C3 precision grade weighing sensor

◆Coriolis pulverized coal feeder adopts sew drive motor.

Ⅲ. Using effects

1 High ratio of material to air

The material-air ratio for conveying pulverized coal by Coriolis coal feeder can reach 4 ~ 5kg / m3. Nearly double above other rotary feeders. It greatly reduces the air volume of conveying pulverized coal and reduces the energy consumption of Roots blower. According to statistics, the power of Roots blower can be reduced by about 5 ~ 50KW in different production lines.

2 Reduce the primary air volume.

There is a certain proportional relationship between the coal supply air volume of burner and that of primary air fan, which is about 1:1.67. Reducing the coal supply air volume also reduces the supply air volume of the primary air fan, which is actually reducing the supply of cold air. In the process, the coal supply air also needs to be heated to the same temperature of the material (about 1000 ℃), and the heat required for 1nm3 cold air to be heated to hot air is 1300KJ.

A 5000t / D production line with Coriolis pulverized coal feeder can reduce the primary air volume of 56000nm3 per day. If calculated by one year USD 95K of raw coal can be saved.

3 The waste gas generation in the kiln decreases, and the waste heat loss of the kiln tail decreases.

The primary air is reduced, the exhaust gas generation in the kiln is reduced, and the heat loss of the exhaust gas discharged from the tail of the kiln is reduced.

4 Increase the combustion rate of pulverized coal

The primary wind is the ambient normal temperature wind. The reduction of the primary wind is bound to increase the volume absorption capacity of the secondary wind. At the same time, the mixed heat flue gas is more likely to be mixed into the flame jet, thus greatly increasing the combustion rate of pulverized coal.

5 Reduce the emissions of harmful gases

The combustion of pulverized coal is more sufficient, the combustion time is shortened, and the generation of harmful gas NOx is significantly reduced.

6 Increase the service life of the burner

Increasing material-air ratio, reduced primary air volume, reduced wind speed, and reduced wind speed in the wind duct, increasing the service life of pipes and burners.

7 Reduce infrastructure investment and save power consumption

Due to the small volume and light weight of the Coriolis pulverized coal feeder, there is no need to make a special foundation to reduce the capital investment. At the same time, there is no need motor drive, which can save power consumption.

Ⅳ. Installation, use and maintenance

The installation height of Coriolis pulverized coal feeder is about 3M, the overall weight is light, and only two embedded steel plates are required. The feeder is connected with the discharge port of pulverized coal silo by flange. The installation of the whole equipment does not need any installation support, and the installation and disassembly are very convenient. The feeder body does not need a dust collector.

System maintenance: lubricating oil shall be added regularly, there is no need for special maintenance and frequent replacement of spare parts. The horizontal star pre feeder and Coriolis metering unit operate independently. Even if the metering unit fails, the star feeder can feed normally, so as to avoid losses caused by shutdown.

There is no friction with the material inside the Coriolis feeder, only a small amount of air passes through the measuring plate, using wear-resistant steel, the service life is more than 5 years, the feeder wall is affixed with wear-resistant ceramics. The overall feeder is almost maintenance-free.

V. Compressed air consumption

Coriolis pulverized coal feeder only needs compressed air to maintain micro positive pressure around the scale body and the bearing of the steady flow feeder, so as to prevent pulverized coal from entering the bearing and affecting the measurement accuracy and bearing life. Each pulverized coal feeder needs compressed air 50nm3 / h. Compared with the rotary feeder, the rotary feeder is equipped with a small steady flow bin, and a rotary agitator is configured at the bottom of the bin. The agitator needs compressed air for auxiliary mixing to facilitate uniform and stable feeding of pulverized coal. The manufacturer requires each agitator to provide compressed air of 100nm3 / h, and each rotor scale needs compressed air of 112nm3 / h. Coriolis pulverized coal feeder consumes relatively less compressed air.

VI. Applications

The following is our coal feeder’s application in one of customer’s 2500T clinker reform production line.

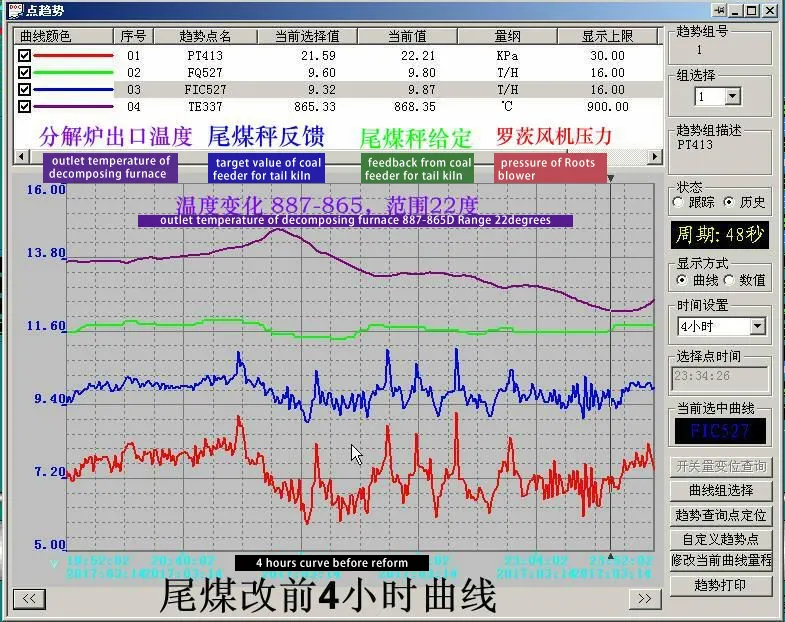

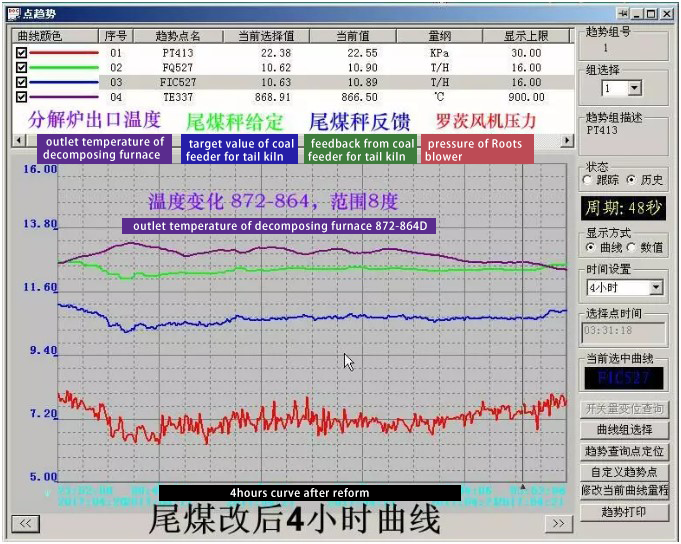

The green line in the figure shows the central control dosing of coal feeder for tail kiln. When the central control dosing does not change, the feedback of coal feeder for tail kiln presents a small fluctuation curve, indicating that the locking of the coal feeder is not tight, and the control cabinet is adjusting by adjusting the frequency of the frequency adaptor. The severe fluctuation curve indicates that there is no uniform incoming material in the feeding mechanism, and the situation of more or less materials occurs frequently, resulting in feedback fluctuation, and corresponding fluctuation in the pressure curve of Roots blower. When adjusting the feeding quantity, because the feeding mechanism adopts a series structure, it can not quickly meet the feeding, so there is a large frequent fluctuation adjustment.

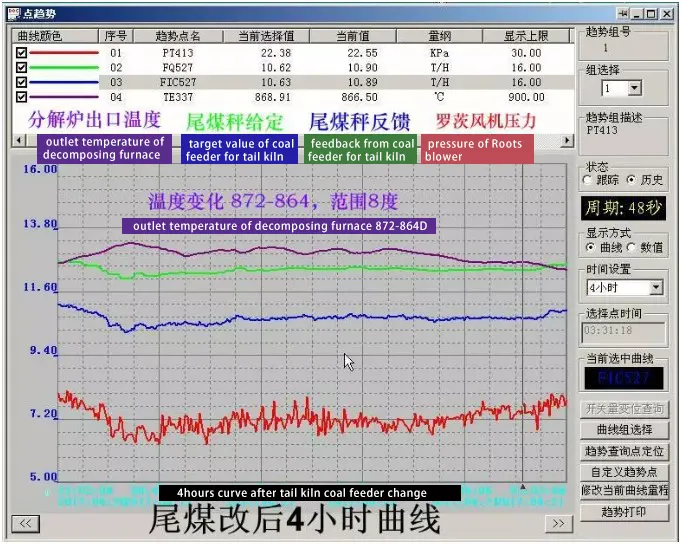

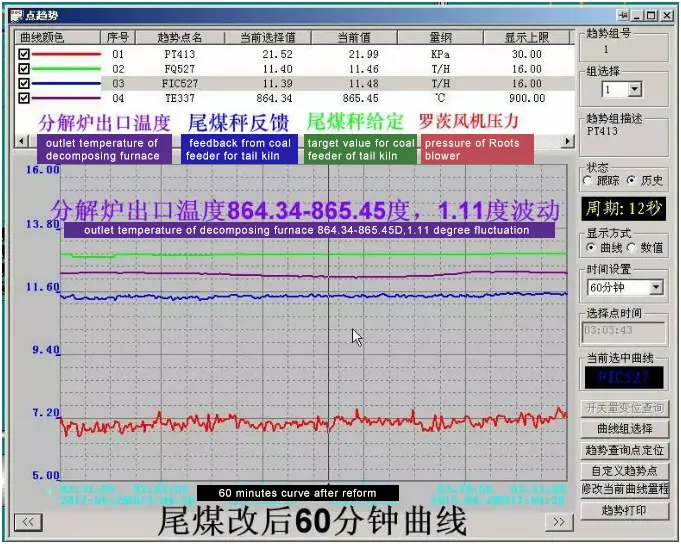

Operation curve of our company’s new coal feeder after it is put into use:

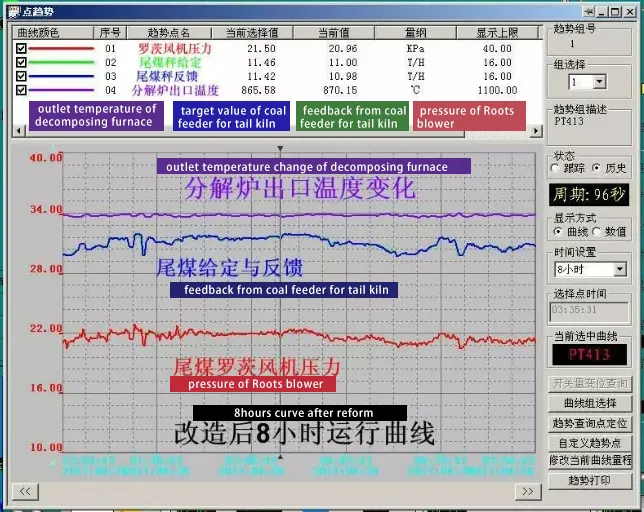

The curve is the 8-hour operation curve of coal feeder for tail kiln on April 26, 2017.

As the steady flow feeder has the function of material locking, the feeding quantity and feedback quantity are timely and accurate, and basically coincide. The pressure of Roots blower for coal feeder for tail kiln is stable, with a fluctuation range of 20.39-22.4mpa.

The outlet temperature of calciner is stable between 860-876 ℃.

In conclusion, for the cement clinker firing system, the use of Coriolis pulverized coal feeder has great advantages in energy conservation and emission reduction. From the analysis of economic benefits, the annual power consumption of typical 5000tpd clinker production line is nearly 2 million kWh and the coal consumption is about 4200 tons. Coriolis pulverized coal feeder has no worn parts and is easy to operate and maintain. Coriolis pulverized coal feeder has high feeding accuracy and stability, and the kiln condition is easy to ensure. In terms of equipment cost, the primary investment and long-term maintenance cost of cement manufacturers are reduced. Coriolis pulverized coal feeder has great advantages as pulverized coal metering equipment in cement industry.